I always enjoy prints that just become part of our lives (and especially ones that let us keep using something that's going to the landfill otherwise)

The hamper has handles that break. For most people I think that'd be time to replace it. I didn't want to do that, so I designed a new handle based on the handle on the short end. This ended up being a mistake later, I'll explain then.

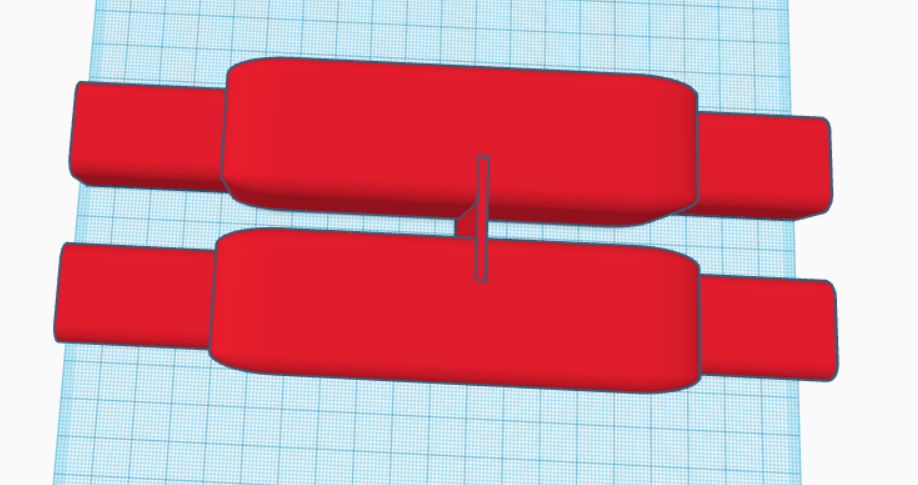

I printed 2 handles (the connection between the two is just to make the printing work better since it can print the two pieces as one piece, then I just snap the two apart and clean up the spot they were connected)

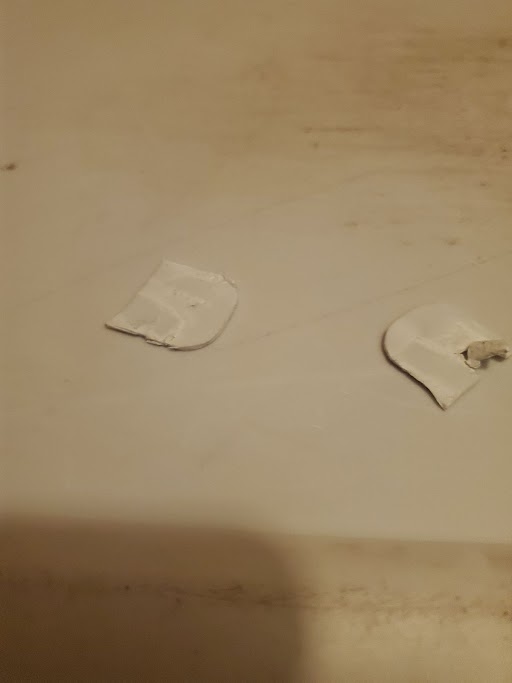

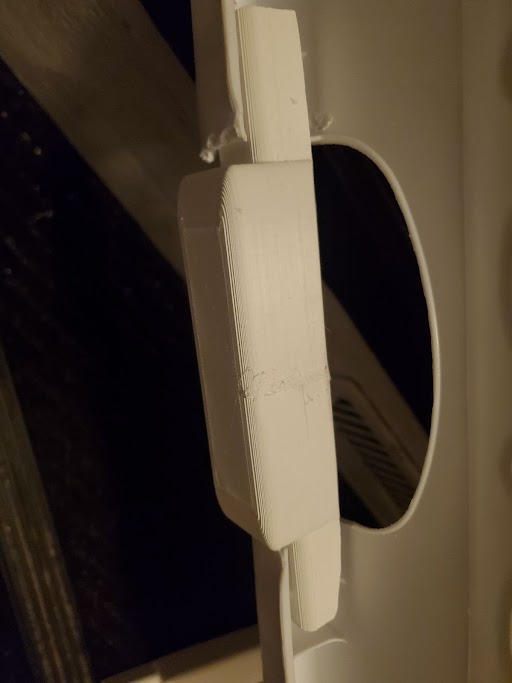

I used my rotary tool to remove the remnants of the original handles. I should have used the cutting tool but I had the diamond grinder so I used that. It worked fine, I was able to fully remove the old material. A quick test fit confirmed that the handle design was pretty good (I just used a tape measure for the measurements so this was a real potential problem)

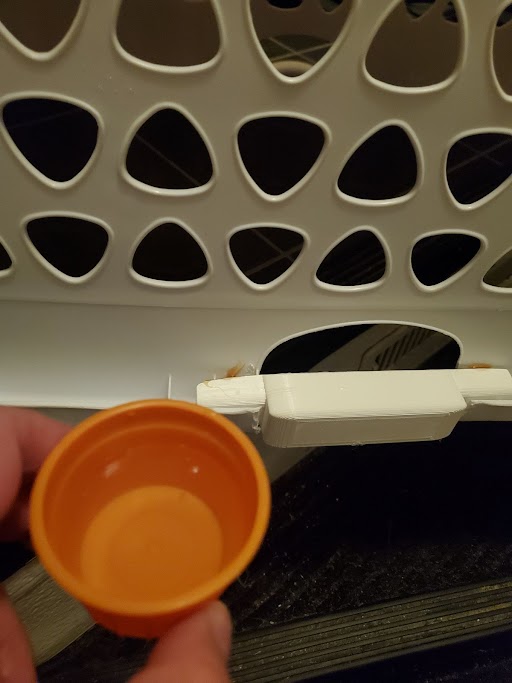

I went to the long side, but realized that the design of the hamper was different lengthwise than widthwise. I removed a couple tabs that were going to block the new handle, and instead of putting it in as designed, I just put it sideways, which fit.

I put the two in and added gorilla glue. Gorilla glue requires water to foam up, so I wet all the parts. Now everything is fitted, the glue is in, and it's just drying now. I'd consider this repair a success, and I expect the strong PLA part to give the whole hamper a lot more stiffness at those parts, and there's significantly more material in these spots that break. If the other two handles break, I'll just print two more, and at that point I can't help but think that the hamper will be bulletproof.

The hamper has handles that break. For most people I think that'd be time to replace it. I didn't want to do that, so I designed a new handle based on the handle on the short end. This ended up being a mistake later, I'll explain then.

I printed 2 handles (the connection between the two is just to make the printing work better since it can print the two pieces as one piece, then I just snap the two apart and clean up the spot they were connected)

I used my rotary tool to remove the remnants of the original handles. I should have used the cutting tool but I had the diamond grinder so I used that. It worked fine, I was able to fully remove the old material. A quick test fit confirmed that the handle design was pretty good (I just used a tape measure for the measurements so this was a real potential problem)

I went to the long side, but realized that the design of the hamper was different lengthwise than widthwise. I removed a couple tabs that were going to block the new handle, and instead of putting it in as designed, I just put it sideways, which fit.

I put the two in and added gorilla glue. Gorilla glue requires water to foam up, so I wet all the parts. Now everything is fitted, the glue is in, and it's just drying now. I'd consider this repair a success, and I expect the strong PLA part to give the whole hamper a lot more stiffness at those parts, and there's significantly more material in these spots that break. If the other two handles break, I'll just print two more, and at that point I can't help but think that the hamper will be bulletproof.

- replies

- 3

- announces

- 4

- likes

- 2

Money is time, so if you can save a 20 dollar hamper with 2 cents of plastic that's a win imo. Especially if the repair means a common failure point is addressed and something you might need to buy again and again lasts a lifetime.